Signage

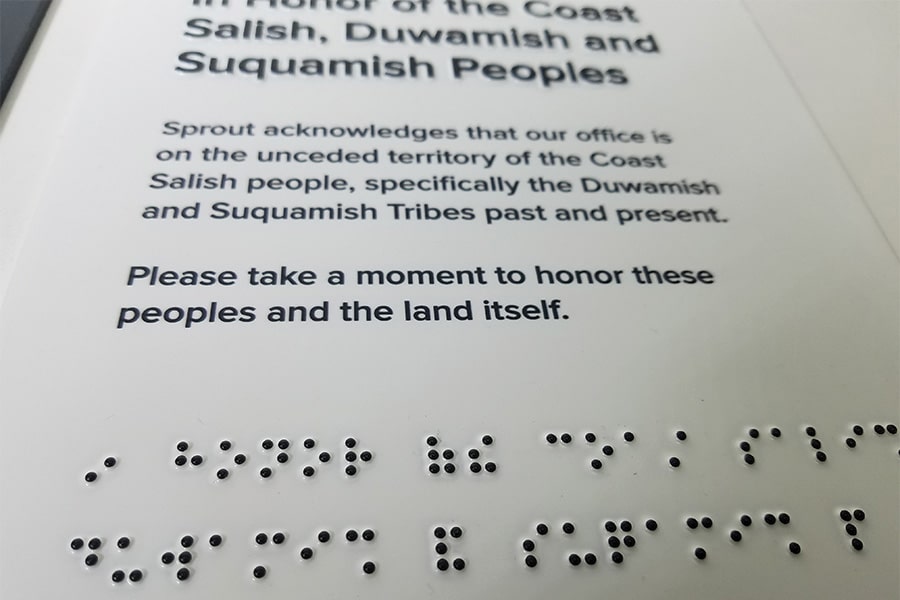

Photopolymer

Petersen Brothers are industry leaders in processing and finishing photopolymer signage, offering high-quality, wholesale ADA-compliant signs.

Our custom photopolymer signage is available in both interior and exterior-grade materials, with multiple thickness options to meet your specific needs.

Get a quote

What is Photopolymer?

Photopolymer is a light-activated resin and one of the most durable and reliable choices for ADA-compliant signage. This material is crafted from a single piece of UV-reactive resin that, when processed, hardens into a strong, layered plate. Known for its exceptional resilience, photopolymer is the go-to solution for facilities where durability and vandal resistance are essential.

Its versatility makes it ideal for ADA-compliant signage, especially in high-traffic environments such as hospitals, government buildings, and schools.

Applications of Photopolymer Signs

- ADA Compliant

- Room Identification Signage

- Wayfinding Signs

- Safety and Compliance Signs

- Restroom and Facilities Signage

Characteristics of Photopolymer Signs

- The Most Durable ADA Compliant Signage

- Crafted from a Singular Piece of UV Reactive Material

- Customizable Designs & Finishes

- Resistant to Vandalism

- Interior and Exterior Rated

Petersen Brothers Photopolymer Material Specifications

| Thickness | Type | Sheet Size |

|---|---|---|

| .020” | Non-glare Sign Base | 19" x 25" |

| 1/16” | Non-glare Sign Base | 19″ x 25″ |

| 1/8" | Non-glare Sign Base | 19″ x 25″ |

| 3/16" | Non-glare Sign Base | 19″ x 25″ |

| 1/4" | Non-glare Sign Base | 19″ x 25″ |

| 3/8" | Gloss Sign Base | 19" x 25" |

What’s the difference between Acrylic and Photopolymer signs?

When comparing Acrylic and Photopolymer signage, several key differences stand out. The most significant is durability—Photopolymer signs are more robust, highly resistant to vandalism, and built to withstand the elements.

The manufacturing process also sets them apart. Photopolymer requires specialized equipment and techniques, while Acrylic fabrication is more straightforward. Additionally, material costs play a role—Photopolymer is a more specialized and costly material, contributing to its higher price point.

These distinctions make each material ideal for different applications. When selecting the best signage for your project, consider factors such as design, budget, durability needs, and timeline.

We look forward to assisting you with your next Photopolymer signage project!

About The Photopolymer Process

Photopolymer signage is created through a precise process that utilizes photosensitive polymer resin and ultraviolet (UV) light. The process begins with transferring a digital design onto a clear transfer film. The top layer of the photopolymer resin is then exposed to UV light, causing it to harden. Any resin not exposed to UV remains soft and is washed away, forming the raised elements of the sign.

Once the design is set, the sign is dried and undergoes a final UV exposure to ensure complete curing. At this stage, the sign blank is ready for finishing. The raised elements are decorated using painting, rolling, or stamping techniques, and the entire sign is sealed with a UV-resistant topcoat for added durability.

This meticulous process results in the most durable and long-lasting ADA-compliant signage available, making photopolymer an ideal choice for high-traffic and high-impact environments.

Contact us today to discuss your Photopolymer signage needs.

Contact Us